Number of En-Fold Units on a Single Control System

From a single (twelve drive beam) unit up to 6 (two drive beam) units can be operated with a single

control system.

Fabric Support Beam Length (Overall Width)

The width of the En-Fold system can range from as few as 20 feet to over 200 feet in a single unit.

Fabric Support Beam Spacing

The fabric support beam spacing ranges from 2 feet to 5 feet and depends on the drive beam spacing and

the maximum allowable wind pressure required for the application.

Tru-Tension - Multi-Position Extension System

Up to three, fully tensioned, stopping points for the En-Fold canopy. With the Tru-Tension system the

operator is able to easily extend the canopy to a variety of positions to provide just the right amount

of shade, airflow, or rain protection while ensuring that the fabric canopy is fully tensioned and safe

from the damage that is caused by lose fabric fluttering in the wind.

Drive Beam Span

From 20 feet up to 45 feet in continuous extruded aluminum profiles

From 45 feet up to 90 feet in spliced extruded aluminum profiles

Number of Drive Beams

A single En-Fold unit can have as few as 2 drive beams or as many as 12 drive beams

Drive Beam Spacing

The standard drive beam spacing is up to 20 feet on center with spacing of up to 28 feet on center with

reduced wind loading.

Curved Fabric Support Beams

A slight pre-camber can be rolled into the fabric support beams when drive beam spacing is pushed to the

limits to ensure proper drainage

Edge Overhang

Cantilevered edges from a minimum of 12 1/2 inches up to a maximum of 8 foot 6 inches, or 35 percent of

the drive beam spacing is possible

Drive Beam Connections

En-Fold drive beams can be supported by a number of standard wall mount, column mount, and transfer beam

mount brackets or can mount to the bottom surface of supplemental support beams

True-Tension® technology

True-Tension® technology

En-Fold’s patented Tru-Tension® technology allows users to deploy the awning at three

points—one-third, one-half, and two thirds—yet remain fully in tension for top performance, while

providing the optimal amount of shade, airflow, or protection from precipitation.

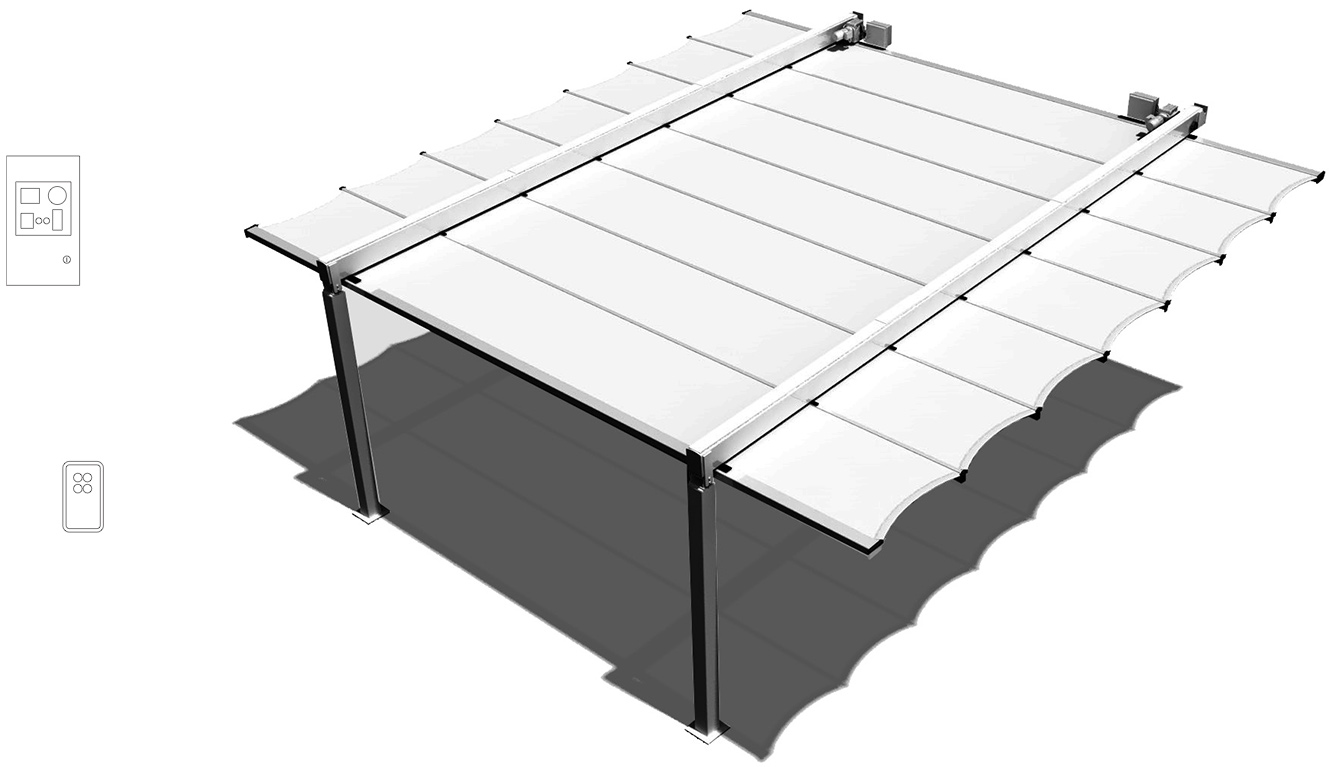

Drive Beams

Drive Beams

The primary horizontal supports, En-Fold drive beams are constructed of 1/4” thick extruded aluminum.

Measuring 11-1/16” x 7-5/8”, these beams dwarf the competition. Why so robust? For strength, certainly.

But equally important, for minimalist aesthetics. Larger but far fewer beams means fewer visual

obstructions. When En-Fold is retracted, it’s virtually all sky - not a lattice work of beams.

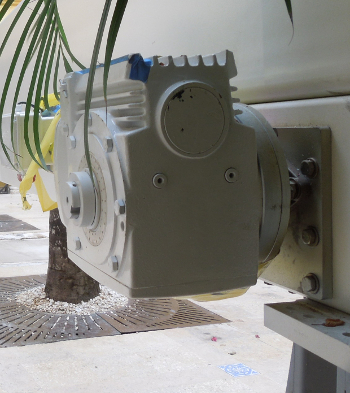

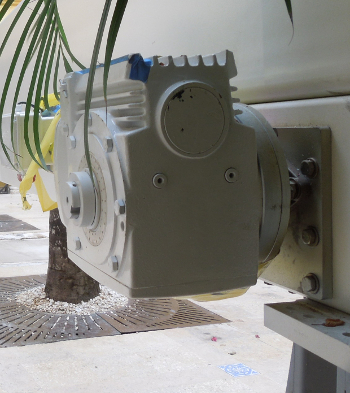

Motors

Motors

Powerful yet compact and remarkably quiet 3/4 HP electric synchronized gear motors smoothly deploy and

retract the En-Fold awning. Motors are cleanly concealed and protected within aluminum housings.

Architectural Fabric Membrane

Architectural Fabric Membrane

Not your ordinary awning fabric (like canvas), with En-Fold you get a top-grade, precision-woven

architectural fabric membrane—the very same used on the world’s premiere stadiums. En-Fold fabrics are

engineered to endure decade after decade, remain brilliantly pristine, block UV rays, and beautifully

diffuse light.

Leading Edge Beam

Leading Edge Beam

This extruded aluminum beam is deployed and retracted to open and close the En-Fold awning.

Idler Beams

Idler Beams

Spaced every 4-1/2’, extruded aluminum En-Fold idler beams hold fabric membrane panels securely in

tension and create a weathertight seal.

Edge Cable Assembly

Edge Cable Assembly

Edge cable assemblies—made from Dyneema® rope that is 15 times stronger than steel—located along both

sides of the awning and within each fabric membrane panel, create a true architectural tensile membrane

structure when deployed.

En-Fold Remote

En-Fold Remote

Deploying and retracting your En-Fold awning is in the palm of your hand. En-Fold remote’s rugged

protective housing is ergonomic and easy to grip.

Command Center

Command Center

The brains of the operation, En-Fold’s touch-screen command center is securely located nearby under lock

and key. The command center receives and responds to signals from the En-Fold remote, En-Fold wind and

rain sensors, and building automation systems. Uni-Systems engineers can access the command center, via

secure cloud technology, for diagnostics and any technical support you may require.

Structural Framing

Structural Framing

Fully customizable to match the requirements of your space, En-Fold’s all extruded aluminum or high

strength steel structural framing is constructed for the ultimate in sleekness and strength.

True-Tension® technology

True-Tension® technology

Drive Beams

Drive Beams

Motors

Motors

Architectural Fabric Membrane

Architectural Fabric Membrane

Leading Edge Beam

Leading Edge Beam

Idler Beams

Idler Beams

Edge Cable Assembly

Edge Cable Assembly

En-Fold Remote

En-Fold Remote

Command Center

Command Center

Structural Framing

Structural Framing